Dongnam Realize, under the leadership of Chungnam National University, conducted a comparative study on CXP made from wood, wood+biochar, oyster shells(waste shell), and calcium carbonate against general PP, in collaboration with Hyundai Motor Company and Mika. The study was published in Fibers and Polymers.

For convenience of analysis, the study treated CXP as equivalent to PP without considering the ethylene chain degradation process of CXP. Instead of focusing on general physical properties, the research examined various functional characteristics such as oxygen transmission rate (OTR), water vapor transmission rate (WVTR), thermal conductivity, and thermal diffusivity.

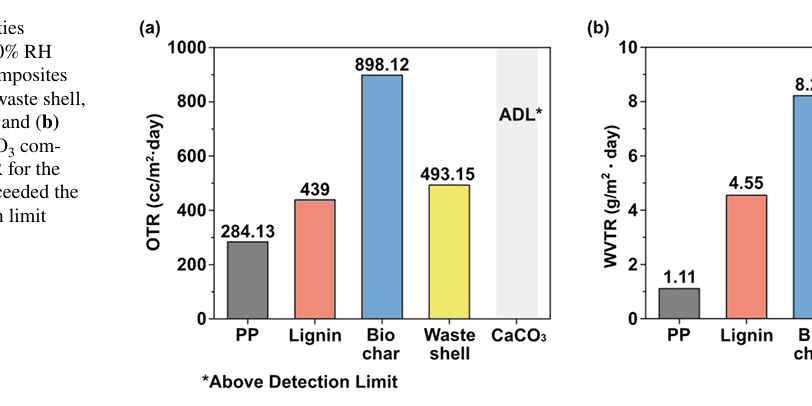

The results confirmed that the most widely used wood CXP had an oxygen transmission rate 1.5 times higher than PP (284), and a water vapor transmission rate about four times higher (1.11 vs. 4.55). Changes in water contact angle further demonstrated that CXP is more hydrophilic compared to PP.

However, the most noteworthy finding was with calcium carbonate (limestone) CXP. While oxygen transmission exceeded the measurement limit (thus oxygen could permeate), the water vapor transmission was similar to PP. This indicates it blocks moisture while allowing oxygen to pass through. Typically, such functionality requires multilayer composites of functional materials, but this study shows that it can be achieved with a single material, suggesting significant potential for future functional applications.

This paper was published in Fibers and Polymers on July 29, 2026.